Table of Contents

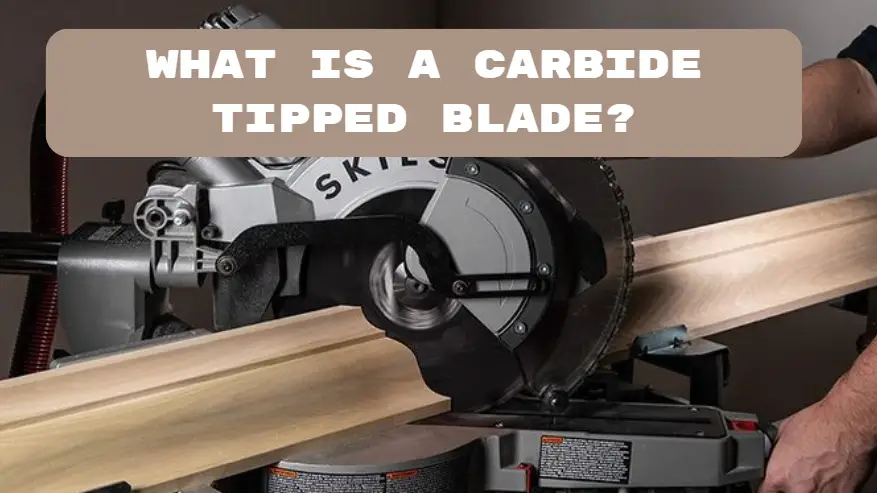

What is a carbide tipped blade?

A carbide-tipped blade is a steel body (arbour/plate) with tiny hard tungsten-carbide inserts brazed or welded onto the teeth. The carbide tips do the cutting while the steel plate supports the tips. This construction combines carbide’s extreme hardness and heat resistance with steel’s flexibility.

Julia Utensili

Why people use them?

Pros

- Stay sharp much longer than plain steel teeth (great for production work or abrasive materials).

- Heat & wear resistance — carbide tolerates higher temperatures and abrasives (e.g., cutting plywood with sand, MDF, or dirty lumber) better than steel.

- Cleaner cuts (when tooth geometry and blade quality are good) — excellent for finish and crosscut blades used in cabinetry and fine woodworking.

- Versatility — available for circular saws, table saws, miter saws, band saws, panel saws, chop saws and specialty metal cutting blades.

Cons

- Cost up front — carbide-tipped blades are noticeably more expensive than plain HSS or carbon steel blades.

- Chipping risk — carbide is very hard but brittle; hitting a nail/staple or misfeeding can chip a tooth. Proper blade selection and feed rate matter.

- Sharpening is specialized — teeth require a diamond wheel (or specialist equipment) for regrind; DIY sharpening is not trivial. Many users send blades to professional sharpening shops.

Types & how to choose for your task

Choose based on material and cut type:

- General-purpose / combo blades (40–50T for 10″ / 60T for 12″) — good for mixed ripping + crosscut on jobsite and home shop.

- Finishing / crosscut blades (60–100+ teeth) — smoother edges; best for plywood, veneered panels and trim.

- Rip blades (fewer teeth, large gullets) — for fast ripping of solid lumber.

- Thin-kerf blades — less material waste and lower motor load (good for cordless or lower-power saws), but may have more vibration.

- Specialty (nonferrous, tile, metal cutting, carbide-tipped band saws) — use blade specifically made for the material (e.g., carbide tipped band-saw for hard, abrasive wood or metals).

Key specs to compare: diameter, arbor size, tooth count & hook angle, kerf width, tooth geometry (ATB, FTG, TCG), coating/finish, anti-vibration features (expansion slots/laser cuts).

Real-world performance & common picks (quick review)

- Freud / Diablo (Diablo D0740A etc.) — widely recommended for clean finish cuts, stays sharp, good value for pros and DIY; strong anti-vibration design and laser-cut stabilizing features. Good “do-it-all” finish blade.

- Forrest Woodworker II — premium blade with excellent edge life and finish; many experienced woodworkers praise longevity (higher price). Community reviews show Forrest holds edge long and has good repair/sharpening support.

- DeWalt / OEM combo packs — practical for jobsite use (value + acceptable quality). Recent roundups list DeWalt combo sets as good DIY/jobsite options.

- Carbide-tipped band saw blades — for resawing slabs and heavy use, carbide tipped bands can last longer but are costly; worth it only when abrasives/contaminants make HSS/bi-metal wear out quickly.

(Takeaway: Diablo/Freud are excellent all-rounders; Forrest is a premium choice if budget allows; DeWalt and other manufacturers offer strong jobsite options.)

Maintenance: clean, inspect, and care

Routine care keeps carbide blades cutting well and extends time between resharpenings:

- Clean pitch/resin build-up after use — use blade cleaners or a simple soak to remove pitch that increases friction and heat. Regular cleaning preserves tooth geometry.

- Inspect for chipped teeth or cracks every session — chips can cause noisy vibration and poor cuts; repair or replace if severe.

- Avoid overheating — correct feed rate and sharpness reduce heat; cutting too slowly (or too hot) harms carbide bond. Use appropriate cut speeds and cooling where relevant.

- Store safely — hang or sleeve blades to prevent accidental damage to carbide tips.

Sharpening & reconditioning

- Carbide teeth require diamond abrasives (diamond wheel/grit) to sharpen; normal whetstones / grinders won’t cut carbide. Proper profile must be maintained — angle, hook, and bevel.

- Professional sharpening is recommended — many shops sharpen carbide blades with dedicated fixtures/diamond wheels; DIY home methods risk changing geometry or cracking tips. If you use blades heavily, sharpening every few resharpenings is cheaper than frequent full replacements.

- How often? Depends on material and workload. A good blade in woodworking can be resharpened multiple times (some shops report 3–4 dressings before tooth replacement or end of life), but abrasive/dirty stock will shorten intervals.

When to replace vs resharpen

- Replace if the blade is warped, teeth lost/too many chips, plate is damaged, or if sharpening would remove tooth geometry. Resharpen if it’s simply dull but straight and intact. Professional sharpeners can advise.

Safety & best practices

- Use proper guards, push sticks, and anti-kickback measures. Carbide blades cut well — but that makes mistakes more dangerous.

- Let a hot blade cool before touching. Clean and disconnect power before changing blades.

- Set correct blade height and fence alignment; use zero-clearance inserts for cleaner finish and to reduce tear-out.

Buying checklist (quick)

- Match diameter + arbor to your saw.

- Choose tooth count & geometry for the cut (rip vs crosscut vs combo vs finish).

- Look for laser cut stabilizers / anti-vibration slots for quieter, truer running.

- Read reviews on edge life and whether the manufacturer offers sharpening/repair support (Forrest often praised for service).

Quick recommended picks (by use)

- Finish / cabinet work: Freud / Diablo D0740A (40–60T finish blades).

- Premium long-life finish: Forrest Woodworker II (higher price, great edge life).

- Jobsite / combo value: DeWalt combo packs or Diablo combo blades (good performance & value).

- Bandsaw resawing / abrasive stock: Carbide tipped band blades from specialist makers — use only when needed due to cost.

Real-world tips from pros

- If you cut a lot of plywood/MDF, the extra cost of carbide pays for itself via less downtime and fewer blade changes.

- For occasional DIYers, a quality Diablo/Freud combo blade is often the sweet spot — good finish, durable, and affordable.

Carbide-Tipped Blade Comparison

| Blade | Specs | Tooth Count | Best Use | Price Range (USD) | Notes |

|---|---|---|---|---|---|

| Diablo Freud D0740A (7-1/4″) | Thin-kerf, ATB grind, Perma-Shield coating | 40T | General purpose / finish cuts (plywood, hardwood, softwood) | $20–$30 | Stays sharp, clean cuts, low friction. Great value DIY blade. |

| DeWalt DW3106P5 (10″, 2-Pack) | Combo set (32T & 60T), ATB grind | 32T / 60T | Jobsite combo — rip & crosscut | $40–$50 (set) | Versatile and affordable for contractors & DIYers. |

| Diablo D1060X (10″) | Ultra-finish, thin-kerf, ATB | 60T | Fine crosscuts, veneered plywood, trim | $45–$60 | Excellent choice for smooth edges; less tear-out. |

| Forrest Woodworker II (10″) | Full-kerf, high-quality carbide, hand-tensioned | 40T | Premium all-purpose (rip + crosscut), cabinetry | $120–$150 | Exceptional cut quality and long edge life; pro favorite. |

| CMT Orange Tools 215.050.10 (10″) | Industrial carbide, laser-cut plate | 50T | Precision woodworking, panels | $90–$110 | Excellent alternative to Forrest at lower cost. |

| Carbide-Tipped Band Saw Blade (Lenox Trimaster, 1″ x 10TPI) | Carbide tips on band body | ~10TPI | Heavy resawing, abrasive wood, non-ferrous metals | $150–$200 | Long life in harsh conditions; specialty use only. |

Top Picks by Budget

- Budget (<$40): Diablo Freud D0740A — best everyday blade for clean cuts at a great price.

- Midrange ($40–$80): Diablo D1060X — great for fine finishing work without breaking the bank.

- Premium ($100+): Forrest Woodworker II — unmatched performance and resharpening support; investment for serious woodworkers.

FAQs

Can I sharpen carbide-tipped blades at home?

Not easily — carbide needs diamond grinding. Small tabletop diamond sharpeners exist for experienced users, but most send blades to a pro. Incorrect DIY sharpening can ruin a blade.

Is carbide better than HSS or bi-metal?

For life between sharpenings and cutting abrasive materials, carbide wins. For impact-heavy, inexpensive applications where cost and ease of resharpening matter, HSS/bi-metal may be preferable. Choose by application.

How long will a carbide blade last?

Widely variable — from hundreds to thousands of board-feet depending on material, contamination, feed rate and care. Users report long life for clean hardwood work; heavy abrasive work reduces life. Expect to be able to resharpen several times if kept in good condition.

READ ALSO: How to fill cracks in wood?