Table of Contents

Southern yellow pine vs douglas fir: What they are?

Southern Yellow Pine

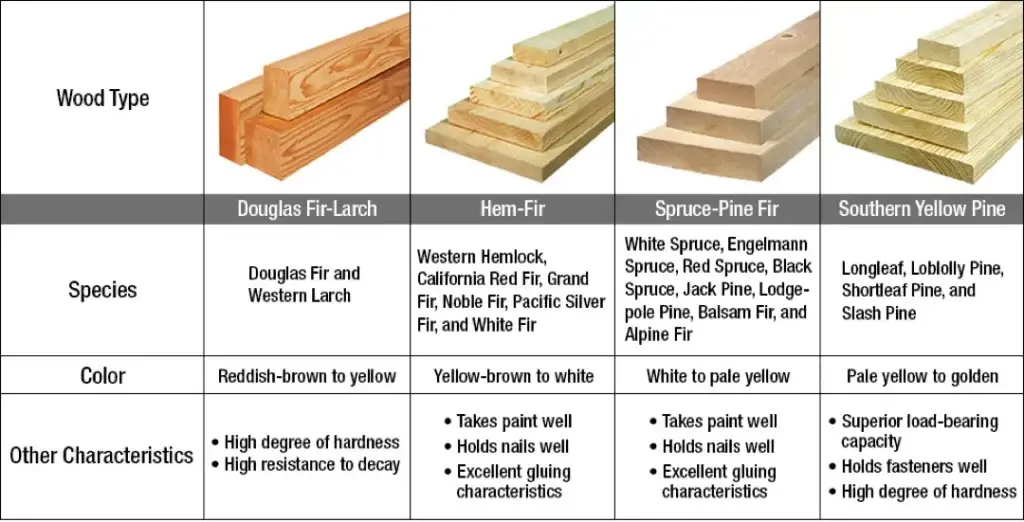

- “Southern Yellow Pine” is a grouping of pine species found in the southeastern U.S., e.g., Loblolly Pine, Shortleaf Pine, etc.

- It tends to be dense for a softwood, strong in bending and compression. For example, one source says: “yellow pine is by far the strongest softwood on our list … highest bending & compression strength of any softwood seen throughout North America.”

- It has high resin/pitch content (sap pockets, etc) in some cases.

- Historically used for heavy-duty structural timber, beams, joists, flooring, outdoor structural uses.

Douglas Fir

- Douglas Fir (technically the genus Pseudotsuga) is a widely used softwood in North America, especially in the western regions.

- It is known for good structural strength, dimensional stability, relatively straight grain, good fastener holding ability.

- Often a go-to for framing, beams, structural uses.

Key Physical & Mechanical Properties & Differences

Here are how they compare in measurable qualities and relevant differences.

Density & Strength

- Southern Yellow Pine: Higher density in many cases than Douglas Fir. For example a study found SYP had a higher average density (in mature wood) than DF in that instance.

- In a “strongest softwoods” list: SYP (or more broadly yellow pine) was ranked at the very top for bending strength & compression strength. Douglas Fir was second.

- So: SYP typically offers higher raw strength (especially in heavy structural use) while DF offers very good strength but not quite the absolute top.

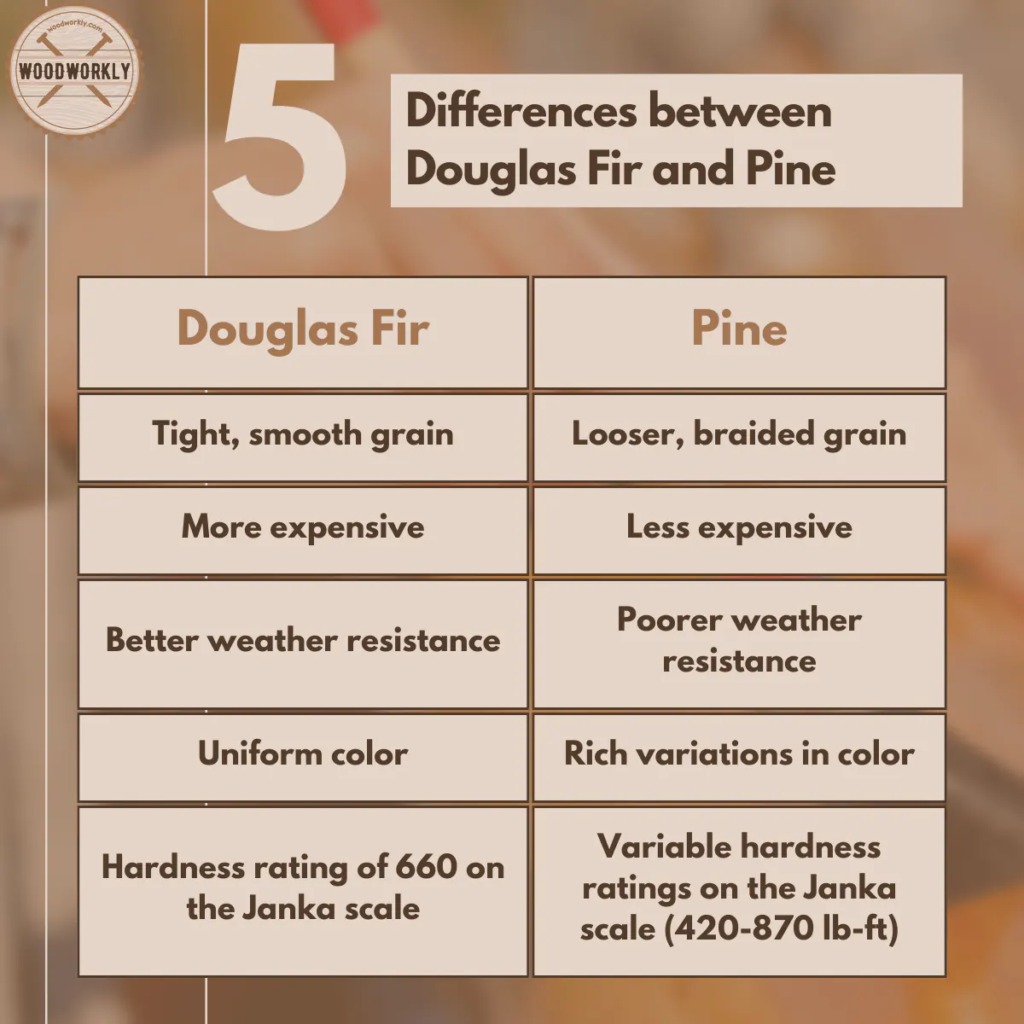

Workability & Grain / Appearance

- Douglas Fir: tends to have straight grain, uniform appearance, easier to finish nicely. Some woodworkers prefer its look.

- Southern Yellow Pine: Grain can be more pronounced, with distinct latewood/earlywood rings (hard latewood vs softer earlywood) which means the texture and behavior may vary.

- SYP’s high resin and pitch content can pose issues (sticky, pitch pockets) if not well dried.

- On the flip side, SYP’s higher density makes it harder to work (cut, nail) compared to something softer. One comparison: “Yellow pine is stronger than fir, but … more prone to bending, swelling, and shrinking than Douglas fir.”

Dimensional Stability & Moisture / Outdoor Behavior

- Douglas Fir: good dimensional stability, less tendency to warp/shrink compared to some species.

- Southern Yellow Pine: though strong, more prone to swelling, shrinking, bending when moisture changes unless properly treated.

- For outdoor/exposed uses: SYP when pressure treated is widely used (for decks, poles). DF can be used outdoors but may require more sealing or protection.

Bonding / Adhesive / Engineered Use

- A technical study comparing the bonding properties of SYP vs DF found differences in chemical composition (SYP higher hemicellulose, lignin, extractives; DF higher cellulose) and in bonding behavior (delamination, adhesive shear strength) though in many practical cases differences were limited.

- This means that when using for engineered products (laminated beams, veneers etc) there may be nuanced performance differences.

Cost & Availability

- Availability depends regionally. For example in some areas DF is more common, in others SYP is more accessible. On forums: one person in the northeast said DF is main structural wood available; in the south SYP is common.

- Relative cost: Some sources suggest DF is more expensive than SYP in many markets (for similar sizes) because of its premium status. One article: “Douglas Fir is typically more expensive than Yellow Pine due to its superior strength and longevity.”

Full Comparison Table

| Category | Southern Yellow Pine (SYP) | Douglas Fir (DF) | Verdict / Best For |

|---|---|---|---|

| Botanical group | Group of Pinus species (Loblolly, Shortleaf, Longleaf, Slash) | Pseudotsuga menziesii | Both are technically softwoods |

| Region | Southeastern U.S. | Western U.S. & Canada | Depends on your local supply |

| Average Density (kg/m³) | ~590 – 620 kg/m³ | ~530 – 560 kg/m³ | SYP is denser |

| Janka Hardness | ~690 lbf (≈ 3100 N) | ~620 lbf (≈ 2750 N) | SYP slightly harder |

| Modulus of Rupture (MOR) | ~12 800 psi (88 MPa) | ~12 400 psi (85 MPa) | Nearly equal; SYP a bit higher |

| Modulus of Elasticity (MOE) | ~1.80 × 10⁶ psi (12.4 GPa) | ~1.90 × 10⁶ psi (13.1 GPa) | DF a bit stiffer (less flex) |

| Compressive Strength (Parallel) | ~7 500 psi (52 MPa) | ~7 230 psi (50 MPa) | SYP slightly stronger in compression |

| Shear Strength | ~1 500 psi (10 MPa) | ~1 350 psi (9.3 MPa) | SYP stronger in shear |

| Dimensional Stability | Prone to swelling & shrinkage if untreated | More stable & less warping | DF better for consistent fit |

| Workability | Harder to cut and nail (dense & resinous) | Easier to saw, plane and finish | DF better for woodworking |

| Resin / Pitch Content | High — can ooze sap if not kiln-dried | Low — clean and dry surface | DF cleaner |

| Appearance / Grain | Bold grain, contrasty early-/late-wood bands | Straight, fine grain, uniform color | DF more refined look |

| Durability (Untreated) | Moderate — decays without treatment | Moderate to good if sealed | Both need protection outdoors |

| Pressure Treatment Performance | Excellent (accepts treatment well) | Fair to poor (less absorption) | SYP ideal for treated lumber |

| Outdoor Suitability | Excellent when pressure-treated | Moderate with sealant only | SYP better for decks & posts |

| Indoor Applications | Heavy-duty flooring, framing | Framing, trim, architectural details | DF looks better indoors |

| Work Tool Wear | Harder on blades & bits | Gentler on tools | DF easier for DIY & joinery |

| Weight (12% MC) | ~35 – 41 lb/ft³ (560 – 650 kg/m³) | ~31 – 34 lb/ft³ (500 – 550 kg/m³) | SYP heavier |

| Nail/Screw Holding | Excellent | Excellent / Very Good | Nearly equal |

| Paint / Stain Finish | Accepts stain well, but can blotch with resin | Finishes smoothly, takes paint evenly | DF easier to finish cleanly |

| Cost (typical U.S.) | ≈ $2.50 – $4.00 / board foot (cheaper regionally) | ≈ $3.50 – $5.50 / board foot | SYP often cheaper in South |

| Environmental Impact | Plantation-grown — fast renewable | Long-growth species — slower renewal | SYP more sustainable by growth rate |

| Best Uses | Decks, posts, floors, heavy frames, treated lumber | Framing, beams, doors, windows, trim | SYP = strength & outdoor; DF = finish & stability |

| Overall Performance | Very strong but less stable and resinous | Slightly less strong but stiffer and cleaner | Tie – depends on project |

Typical Uses & Best Applications

Here’s how each wood tends to be used, and where one may be better than the other.

Southern Yellow Pine – Best uses

- Heavy structural framing: beams, joists, floor systems where strength and load-carrying capacity matter.

- Outdoor uses (especially when pressure-treated) like decks, playground equipment, heavy-duty outdoor structures. Because of density and durability when treated.

- Flooring, heavy use surfaces (in some cases) due to high strength.

- Large dimension lumber where its strength-to-weight ratio is beneficial.

Douglas Fir – Best uses

- Structural framing, especially where dimensional stability and straight grain matter: beams, trusses, rafters.

- Indoor furniture, cabinetry, architectural joinery where appearance matters (grain, finish) and less extreme loads.

- Situations where warping/ shrinking would be problematic and you want more uniform behavior.

- Moderate outdoor use if well protected, though maybe not as robust as treated SYP for extreme exposures.

Pros & Cons Summary

Southern Yellow Pine

Pros

- Very high strength (especially for a softwood).

- Dense and durable under proper treatment/conditions.

- Often more cost-efficient for heavy structural use (depending on region).

Cons

- Harder to machine/ nail / work due to density and resin content.

- May be more susceptible to dimensional changes (swelling, shrinkage) if moisture control is poor.

- Resin/pitch issues (sticky pockets) if not well dried.

Douglas Fir

Pros

- Excellent structural performance and stability.

- Straight grain, good appearance for finish work.

- Easier to work and finish (relatively) compared to denser woods

Cons

- Slightly lower maximum strength vs the strongest SYP boards (though still very strong).

- More expensive in certain regions.

- For extreme outdoor exposure, may require more care/treatment than pressure-treated SYP.

How to Choose: Which to Use When

Here are guidelines based on project types and priorities:

- If your main goal is heavy structural strength (large spans, heavy loads) and you have access to good quality SYP: SYP is an excellent choice.

- If you care heavily about finish, appearance, straight grain, and less machining difficulty, and the loads are moderate: DF may be the better choice.

- Outdoor, exposed to weather: If you pick SYP, go for pressure-treated species for durability. DF can work if sealed and in less extreme environments, but may not outperform treated SYP in harsh exposure.

- Budget/availability: Check what’s locally available. If SYP is much cheaper and accessible, it might make sense. If DF is more accessible and you want the appearance/finish advantages, go DF.

- Workability and machine/hand tools: If you’re doing fine woodworking or furniture, DF might present fewer challenges. If you’re doing heavy structural framing and appearance isn’t the priority, SYP might be better.

- Moisture/dimensional considerations: If moisture variation is expected (outdoor, variable humidity), leaning toward the more stable wood (DF) or ensuring proper drying/treatment if using SYP is advisable.

Final Verdict

In short:

- If I had to pick one general “better” for versatility, especially where appearance, finish and moderate structural strength matter, I might lean toward Douglas Fir.

- If I had to pick one for sheer strength and heavy structural duty, especially where cost is critical and appearance is less important, I would lean toward Southern Yellow Pine (assuming good quality and proper treatment).

- Ultimately the “best” choice depends on your specific project, local availability, budget, environment (indoor/outdoor), and finish / appearance vs strength trade-offs.

Quick Summary

| If you need… | Choose This Wood |

|---|---|

| Maximum strength / load capacity | Southern Yellow Pine |

| Dimensional stability / less warp | Douglas Fir |

| Pressure-treated outdoor use | Southern Yellow Pine |

| Fine appearance and finish work | Douglas Fir |

| Budget / cost efficiency | Southern Yellow Pine |

| Easy cutting / hand tools | Douglas Fir |

READ ALSO: How long does untreated wood last outside?