Chainsaws are essential if you perform wood-cutting tasks regularly. They are powerful and efficient and can easily cut tough materials. But have you ever wondered how to take your chainsaw to the next level?

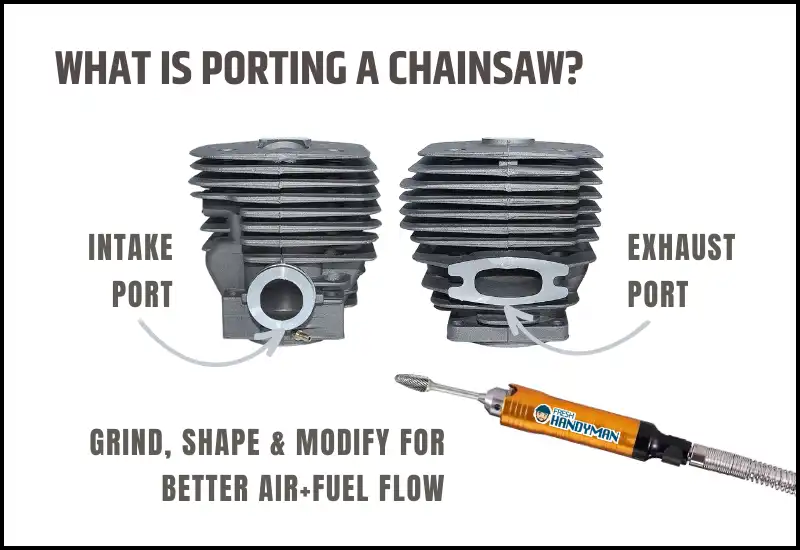

This is where porting a chainsaw comes in. What is porting a chainsaw? It involves improving the performance of your chainsaw by altering the intake and exhaust ports or making other modifications to the internal combustion engine.

Most users port their chainsaws to increase the engine’s power output. However, porting also increases the chainsaw’s torque, speed, and fuel efficiency.

In this post, I will dive into everything you need to know about porting a chainsaw, including the tools you’ll need, the step-by-step process, the benefits and risks, and so much more. Stick around to find out more.

What is Porting a Chainsaw?

Porting involves modifying the engine of a chainsaw by expanding the intake and exhaust ports. These ports control the air and fuel flowing in and out of the engine.

By enlarging and shaping these ports, more air and fuel can enter the engine, enhancing performance. How does porting work? It typically involves grinding and shaping the ports using specialized tools like rotary grinders, files, and Dremel tools.

Porting can increase the power output of a chainsaw, thus making it easier to perform demanding cutting tasks such as felling large trees. However, expanding the intake and exhaust ports is not the only way to port a chainsaw. Here are some other methods:

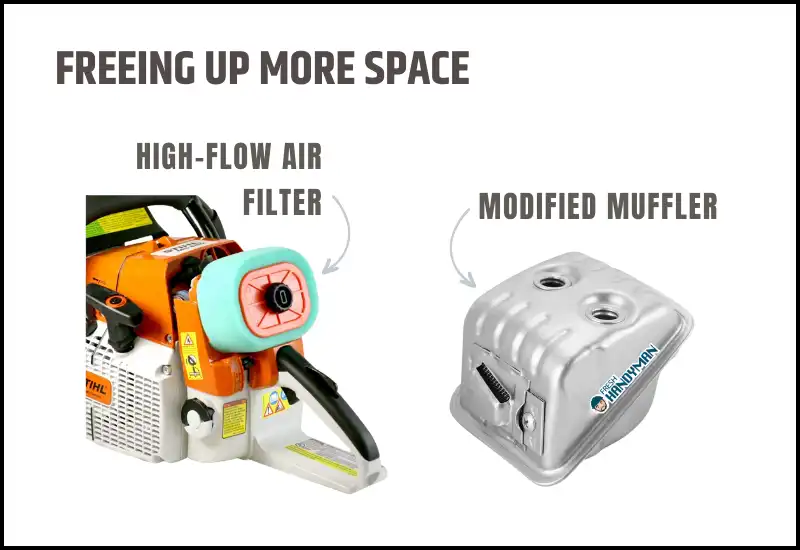

Freeing Up More Space

One way you can port your chainsaw is by removing unnecessary components from its interior to create more space in the intake and exhaust systems of the engine. For example, you can install a high-flow air filter to replace your saw’s stock filter, which can sometimes obstruct airflow.

Squishing

Squishing can be another effective method of improving the performance of the chainsaw engine. It involves reducing the clearance between the piston and cylinder head ( the squish) so that the fuel-air mixture in the combustion chamber is compressed more tightly.

This leads to a more complete combustion and increased power output. The clearance distance is usually reduced by machining or grinding the cylinder head. Additionally, you can use a thin gasket to reduce that distance.

However, you shouldn’t attempt to perform squishing unless you’re a professional or understand how chainsaw mechanics work. Excessive squishing can lead to engine knock, overheating, and other issues.

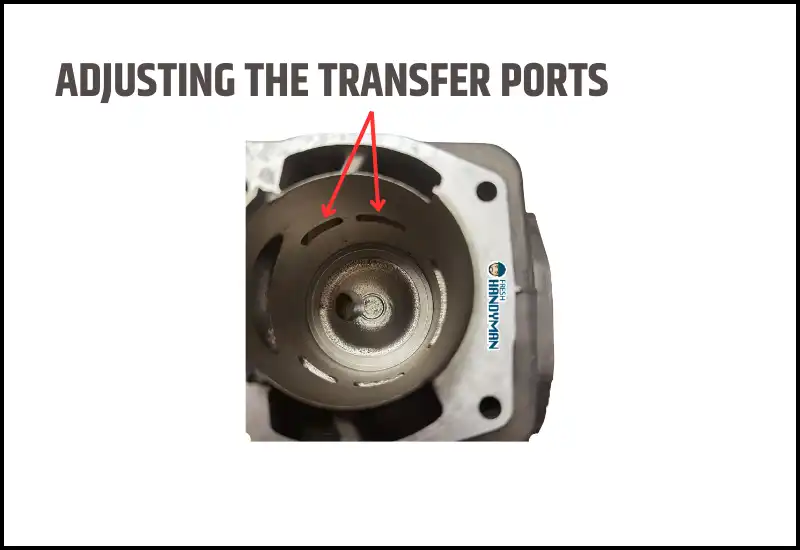

Adjusting the Transfer Ports

You can modify the size and shape of the transfer ports using rotary grinding tools to optimize the fuel-air mixture flow into the combustion chamber. By doing this, the mechanical timing of the transfer ports is improved. This enhances the performance of the engine.

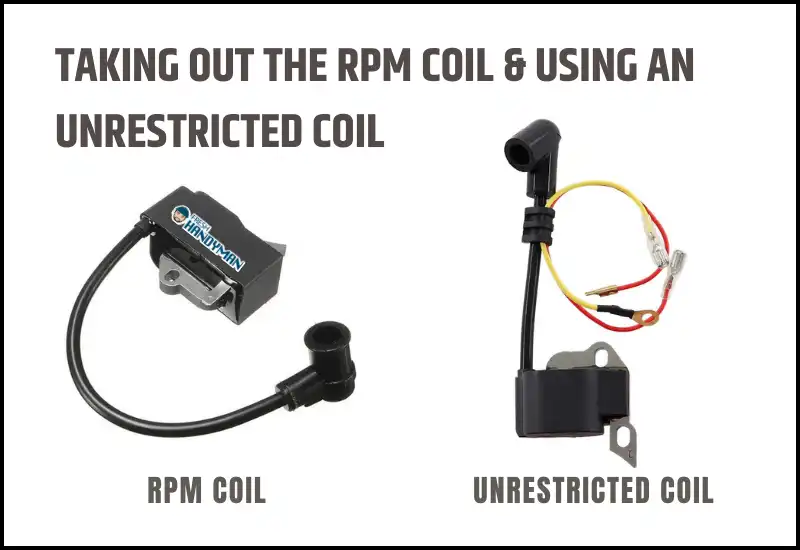

Taking Out the RPM Coil and Using an Unrestricted Coil

Another way you can boost your chainsaw’s performance is by removing the RPM coil and replacing it with an unrestricted coil. Although this will increase your engine’s speed, I would not recommend it since it can run too fast, potentially causing damage or injury.

Using Sawdust

The first method to increase your chainsaw’s performance is adding sawdust to the fuel-air mixture in the combustion chamber. This supercharges the engine while increasing the compression ratio.

However, this method is not recommended because it causes the engine to overheat, lose power and eventually fail. Additionally, sawdust particles are abrasive and can cause increased wear and tear, gradually destroying the combustion chamber. I would advise you to use other porting methods before using sawdust.

Is Porting a Chainsaw Worth It?

Yes, porting a chainsaw can be worth it if done correctly.

Porting a chainsaw can potentially increase its power output, torque, and fuel efficiency. It can also improve the throttle response and reduce engine heat, so it might be useful if you need optimal performance.

Tools and Materials Needed for Porting

Below are some of the most commonly used tools and materials when it comes to chainsaw porting, which you can find:

- A Rotary Tool

A rotary tool is essential for porting a chainsaw since it is used to grind, shape and polish the existing ports or the ports you drilled. The Dremel rotary tool is very popular compared to other models and brands available.

- Drill Bits

Drill bits are used to enlarge the intake and exhaust ports. It is important to have a variety of drill bits so you can make different-sized ports.

- Cleaning Rags or Towels

Cleaning rags or towels are essential in wiping down the chainsaw parts to remove oil or other unwanted debris during porting.

- Screwdrivers

Screwdrivers are commonly used tools for porting a chainsaw. This is because they assist in removing bolts and screws that hold the chainsaw components together during disassembly.

It is important to note that you might need different types of screwdrivers for other chainsaws, so ensure you pick the right one for the task.

- Gasket

You might need to seal the cylinder after porting your chainsaw, and that is where a new gasket comes in handy, so make sure you have one.

- Measuring Tools

Measuring tools such as calipers or micrometer screw gauges will be crucial when it comes to measuring the size of the ports before and after porting.

- Carbide Burrs

This tool removes material from the ports and shapes it quickly. You can easily find a carbide burr set.

- Replacement Parts

Depending on the condition of your chainsaw and its components, you might need a few replacement parts nearby to substitute damaged or worn-out parts. For example, spark plugs, air filters, e.t.c

- Metal Files

Your tool kit should not miss a couple of metal files because you will use them to smooth out the ports after they have been ground.

Safety Gear Needed for Porting

Porting a chainsaw is a fairly simple process. However, it is essential to maintain good safety standards. Here are some of the safety gear that you might need:

- Safety Goggles

You will need safety goggles to protect your eyes from metal shavings or any other debris produced when you grind or drill.

- Respiratory Mask

A respiratory mask is important as it helps to protect you from inhaling fine metal shavings or other harmful debris.

- Apron

A work apron covers your body so that you don’t get injured accidentally by metal shavings thrown off the saw.

Read Also: Bar and Chain Oil: Does Weight Matter?

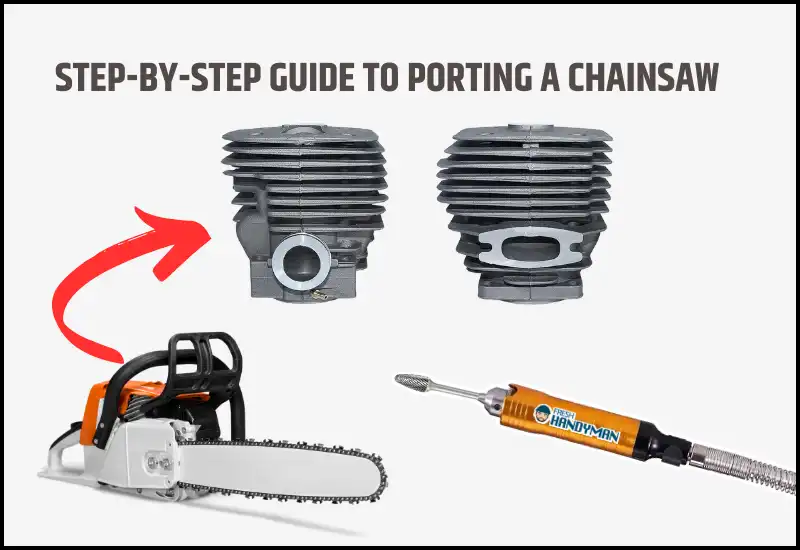

Step-by-Step Guide to Porting a Chainsaw

Now, I’ll give you the step-by-step procedure that you can follow to port your chainsaw:

Step 1: Preparation

Before embarking on porting a chainsaw, you should gather all the required tools and materials (all of which I have mentioned above). If you’re going to need any replacement parts, ensure that they are on standby.

Step 2: Disassembly of The Chainsaw

Next, remove the chain, bar, spark plug, air filter, and other components that may interfere with accessing the cylinder and ports. You should do this carefully to avoid damaging or misplacing any component.

Pro Tip: Follow the instructions given in the owner’s manual to disassemble your chainsaw.

Step 3: Inspection of Components

Now, check the cylinder, piston, rings, and other parts for wear, damage, or defects that may affect the performance or reliability of the saw. Replace any worn or damaged parts before proceeding.

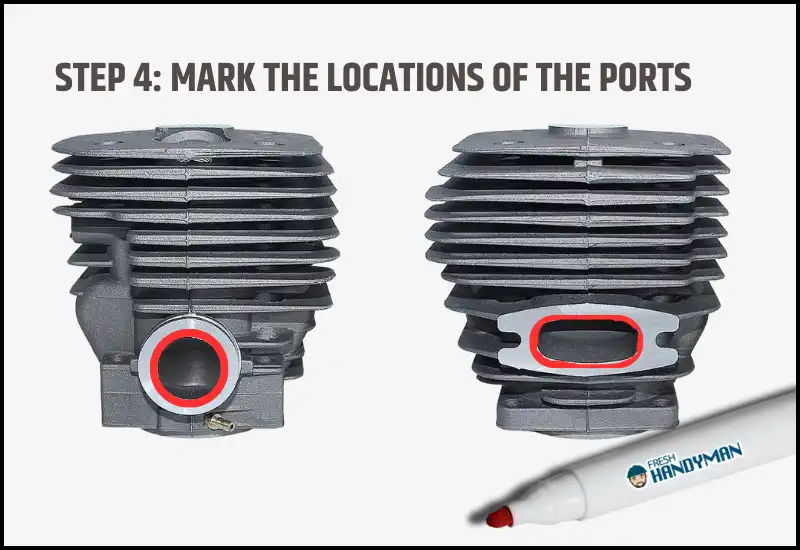

Step 4: Mark the Locations of the Ports

Use a marker pen to outline the shape and position of the intake and exhaust ports on the cylinder. This will help you be as accurate and precise as possible when removing excessive material.

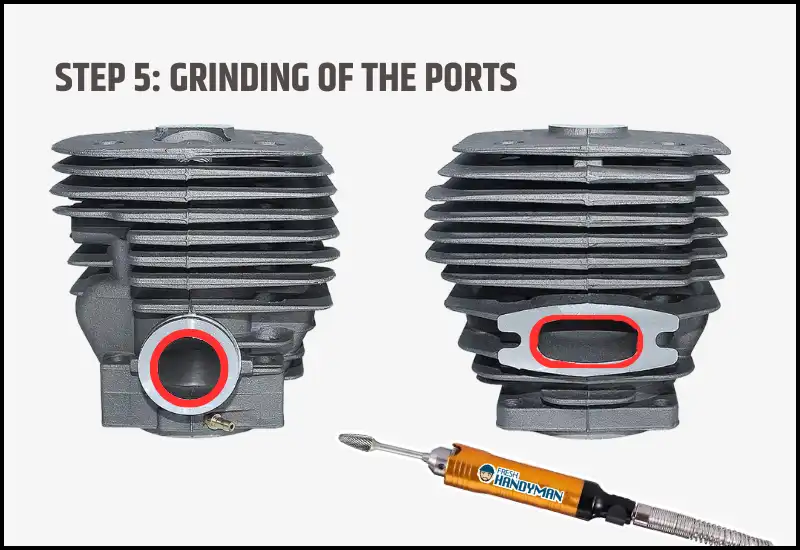

Step 5: Grinding of the Ports

Carefully remove material from the intake and exhaust ports using a rotary or die grinder. You should do this slowly and evenly to ensure the ports are not too large or uneven.

Step 6: Polishing of the Ports

Using a Dremel tool or metal files, polish the surfaces of the ports to smoothen them and eliminate sharp edges.

Step 7: Reassembly of Chainsaw

After you’re done, put the chainsaw back together, ensuring all the components are properly aligned and tightened. It would be best to install all the replacement parts according to the manufacturer’s manual.

Step 8: Carry Out a Test Run

The final step is to test your chainsaw to check if it functions correctly. So, conduct a couple of test runs before you resume using your chainsaw.

Read Also: Chainsaw Chain Catcher: What is it and Why Do You Need One

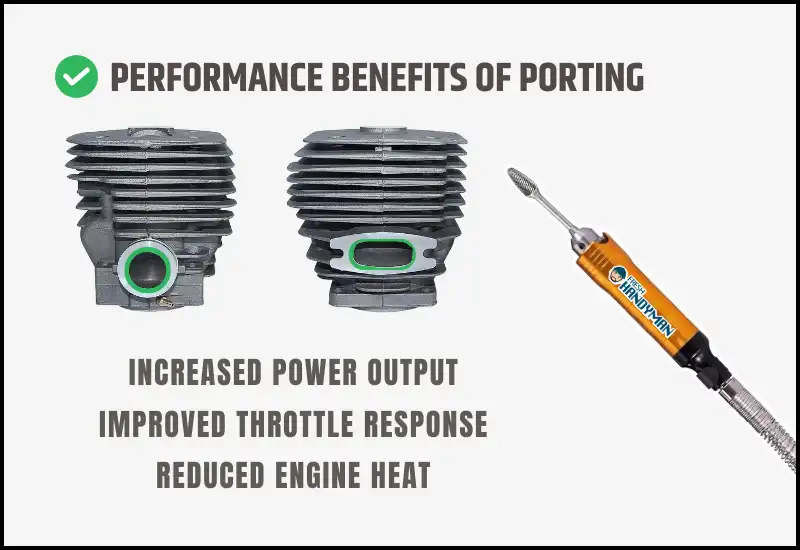

Performance Benefits of Porting

There are several benefits of porting a chainsaw, including:

- Increased Power Output

Enlarging the intake and exhaust ports improves airflow in the engine. This makes combustion better and increases the power output.

- Improved Throttle Response

Another benefit of porting is an improvement in the throttle response. When more air and fuel flow into the engine, it can respond faster to changes in the throttle position. This makes the saw easier to control.

Porting a chainsaw can increase the compression ratio, which positively impacts the chainsaw’s torque. This will make the saw more efficient at cutting through dense wood.

- Reduced Engine Heat

Porting makes the engine more efficient by improving the airflow, thus reducing the amount of heat that it produces. This reduces the chances of damage due to overheating, which increases the saw’s lifespan.

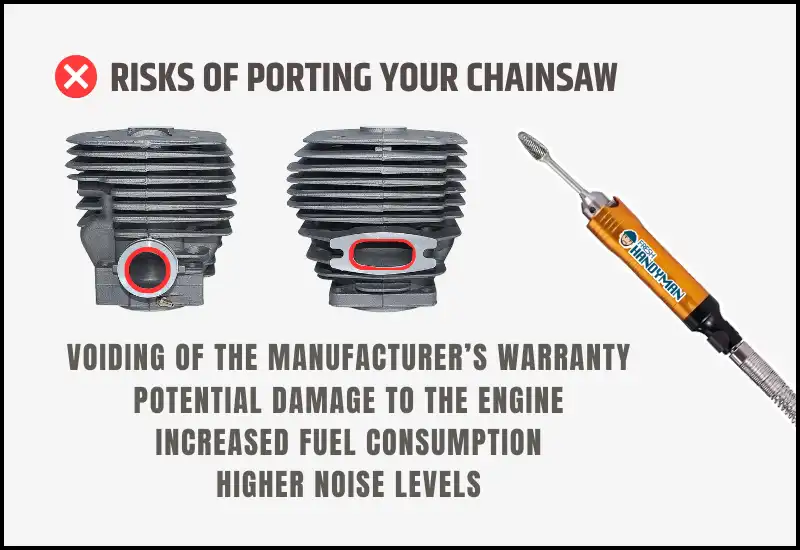

Risks of Porting Your Chainsaw

Although porting can provide many benefits, such as increased power output, it still comes with many risks including:

- Voiding of the Manufacturer’s Warranty

Porting a chainsaw may breach the terms of the manufacturer’s warranty. This is because the warranty usually covers the original configuration of the chainsaw without any alteration.

- Potential Damage to the Engine

Modifying the engine can lead to its damage, especially if not done perfectly. So you should avoid porting unless it is really necessary.

- Increased Fuel Consumption

When you port a chainsaw, its power output also increases. This automatically increases fuel consumption because the engine works harder to produce more power.

- Higher Noise Levels

An increased power output means your chainsaw will run louder than before you ported it. This can cause a disturbance if you’re working near other people, e.g., neighbors.

User Experiences After Porting

One user said that he ported his 71cc Stihl 044, and it felt like someone had bolted a blower onto it. This is because he had lowered the intake and opened the lower transfer ports.

In addition, he raised the exhaust roof and machined the cylinder to hit a .018” squish with the gasket deleted. He advanced the timing and ported the muffler first to achieve a huge power difference.

He also ported a Poulan by drilling a ½” hole clean out the front of the muffler so that it was not restricted. He then filed a keyway notch in the flywheel to let him advance the timing and ran a 92-octane through it. All this resulted in a 30-40% increase in power.

To prevent chipping a cylinder, he recommended cutting at high speed with very little pressure while working with the side of the cutter that pushes the plating toward the cylinder wall.

He warned that porting the wrong way could cost you as he had previously ruined his first cylinder when he chipped the plating and had to buy another $75 Hyway jug.

Another user who ported his Stihl MS 462 said it resulted in a 30% increase in power, adding that the saw could breathe better. He also noted that a good port job would cost you anywhere between 300-400 USD.

DIY Vs Professional Porting

DIY porting involves doing the work yourself using your tools and expertise. This method will be perfect if you know enough about chainsaw engines and porting. It is also very affordable since you will not need to pay for the services of a technician or mechanic.

However, I would advise you to avoid porting alone due to the risks involved. First, if you make even the tiniest mistake during porting, you could irreversibly damage your engine or remain with a poorly performing machine. Additionally, you could void the manufacturer’s warranty.

On the other hand, professional porting is carried out by technicians or mechanics with the right knowledge, skills, experience, and tools to do a thorough job. This approach is generally costlier than DIY porting, but it might help to reduce the risk of your chainsaw developing problems.

However, not every technician or mechanic is up to the task. There are still many quacks who could end up doing a poor job. You should carefully choose your technician, as the quality of the porting job will depend highly on their experience.

Frequently Asked Questions

What kind of performance gains can I expect from porting my chainsaw?

Porting your chainsaw can result in several performance gains, such as increased power output, better throttle response, better torque, and improved cutting efficiency.

Is it possible to port a chainsaw by myself?

Yes, it is possible to port your chainsaw by yourself. However, it requires great skill and knowledge of chainsaw mechanics. It is best to leave it to the professionals if you don’t have enough expertise to avoid damaging your saw.

How much does it cost to port a chainsaw?

Porting a chainsaw can cost between $100- $400, depending on the service provider and the number of modifications you plan to make.

What tools do I need to port a chainsaw?

You might need several tools to port your chainsaw, including a Dremel tool, sandpaper, metal files, calipers, gasket, and carbide burrs.

Conclusion

Porting is a technical and delicate procedure that can cause the chainsaw’s performance to improve immensely. However, it comes with significant risks, so you should take the necessary precautions to ensure that you do not damage your saw or injure yourself during the process.

If you have access to the necessary tools and materials for porting and possess the right skills and experience, you can port your chainsaw yourself. However, if you don’t have the expertise or specialized equipment to guarantee good results, you should seek a professional’s services.

Although it may come at a higher cost, the benefits may outweigh the investment, especially if you use your chainsaw regularly. Regardless of the chosen method, you should properly maintain your saw for it to continue performing at its best.

You Might Also Be Interested In: