Saws have been in use for thousands of years now and have seen significant shifts in design, shape, and functions. In fact, in the last few hundred years, saws have changed so rapidly that it has become almost impossible for anyone to identify all types of saws.

Thus, we decided to take the onus to introduce our valued customers to all the different types of saws so that you at least know the uses of these power tools.

So, are you up for one of the most interesting articles on saws ever?

Different Types of Saws

We have researched extensively in the market to find out 35 different variants of saws. The number itself is overwhelming. And once you learn about all these saws individually, you will feel like unlocking some achievement.

Hence, let’s start the main discussion.

17 Different Types of Handsaws

The following section will describe different types of handsaws with their use.

1. Handsaw

Perhaps, a handsaw is the most ancient and basic type of wood saw. It is a staple for most homeowners to perform different cuts in the home for repairing and fixing purposes.

Although the saw isn’t meant for precise cuts, you can use it for cutting old logs and small wood pieces necessary for repairs and fixes. Besides, it can also cut bones and drywall.

2. Hack Saw

If you need to cut metal or plastics with precision, a hack saw is the best option to go with for you.

It is like a handsaw with a C-shaped frame where the blade attaches itself. The module has 18-32 teeth per inch that help to cut through plastics with ease.

3. Japanese Saws

Japanese saws are used mostly in Japanese carpentry and woodworking. Sometimes, it is called Suzuki.

It has a single handle with durable sharpened blades. Its crosscut helps to initiate the cutting path while rip cuts give every work a subtle finish. Remember that, among all types of wood saws, it is designed for cutting softwoods such a pine.

4. Fret Saw

If you need to cut tight curves in a limited space, the fret saw is your best buy option. It can also perform bevel and delicate cuts with ease.

The saw is also ideal for intricate cuts with as many as 32 teeth per inches for achieving accuracy. Furthermore, its frame is about 10-20 inches long with a 5-inches blade.

5. Keyhole Saw

The shape of a keyhole saw is similar to a swordfish or a standard sword. Despite being a narrow saw, it can perform versatile jobs. Using the keyhole saw, you can perform circular cuts and curve the fret also.

The saw is incredibly lightweight. It works perfectly when you need to cut a small portion of the wall without damaging the interior.

6. Back Saw

A backsaw is often referred to as a handsaw, which is smaller than most other types of saws. It also comes with a thin blade.

It cuts on the edge of the wood or metal and is commonly used with the miter boxes. It is particularly ideal for cutting at 45 degrees and 90 degrees with premium consistency. You will love its accuracy also.

7. Crosscut Saw

Crosscut saw comes with a thick and rugged blade that is helpful for rough cuts of metal and wood. It can also perform perpendicular cuts of the wood with excellent accuracy.

Depending on the work type, crosscut saws are available in different sizes from small to large. Some experts claim that it is the oldest saw and the saw is also handy for camping and tours.

8. Pruning Saw

As the name mostly suggests, a pruning saw is mainly used for trimming tree branches, small plants and cut broken branches of a tree as well.

In most cases, pruning saws are found mounted with a pole to cut tree limbs. The saw is appropriate for reaching low branches and dense vines. The pruning saw offers accurate cuts at a short time effortlessly.

9. Rip-Cut Saw

People often get confused between rip cuts saws and crosscut saws. Although they may look identical, the real difference is in their functions. Rip cut saws are used for framing different metals and wood.

It has sharp teeth but is relatively less in number. Its teeth are angled about 8-degrees backward which works like a sharp knife. If you want fine cuts, choose the rip cut saw.

10. Veneer Saw

The veneer saw comes with a double-edged blade with 13 teeth per inches. The module is, however, limited to 3-4 inches in length.

Its compact size is ideal for cutting hardware veneers. Its double-edged blade is a significant advantage for ensuring precise and quick cuts at the workstation. If you want to cut veneer wood without damaging it, you must get a veneer saw.

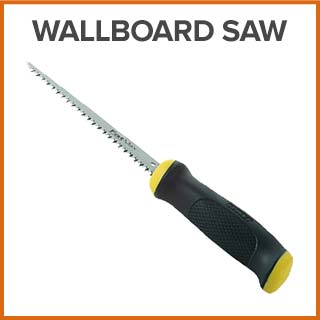

11. Wallboard Saw

Wallboard saws are short sized with broad blades, and it is a regular handsaw tool. Unlike most saw, you can use the wallboard saw with both single and double-edged blades. This is a massive advantage for multi-functions.

12. Bow saw

The shape of a bow saw is identical to a bow with little difference from the handsaw. However, unlike the handsaw, bow saws have a thicker blade with rugged teeth.

This is particularly helpful for cutting through thick plywood and a regular wood board as well. Its sharp teeth make the cutting job quick and convenient.

13. Camping saw

When you pack your camping bags, weight and space become critical. Thus, camping saw with its lightweight, and extremely compact size comes handy.

You can use it to clear your camping area. The saw isn’t handy for large trees but can cut smaller limbs and branches with ease. However, it requires much effort.

14. Folding Saw

Unlike all types of wood saws, as the name suggests, folding saws are foldable. Although the folding saw isn’t as powerful as the other ones, it does perform a small sawing task quite well.

The saw is ideal for camping and trekking. It will help you to whittle the way with sawing, chopping, and other uses.

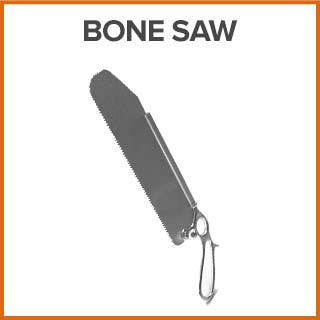

15. Bone Saw

Chefs and meat lovers all over the world know the utility of a bone saw. It is widely used to segregate bones from flesh to prepare tasty stocks for soups.

However, the bone saw is also useable to cut hard metals and wood as well. Nonetheless, due to the handle design, you may find it tough to use the bone saw.

16. Wire saw

Just the name goes, wire saw uses a cable or stiff wire to cut through different materials. Engineers mostly use the saw in laboratories.

It is handy for cutting fragile crystals and subtracts with precision. The wire saw is also used mainly in the mining and quarrying industry for making large blocks with excellent accuracy.

17. Coping Saw

Coping saws have a thin blade with a D-shaped frame. The saw is strong enough to cut metal and wood with ease.

One of the best advantages of the saw is that it comes with interchangeable blades. You can easily replace the blades to perform different cuts. You can perform intricate cuts and trims with the saw.

19 Different Types of Power Saws

The following list described the different types of electric saws and their most common use.

Types Of Band Saw

1. Bandsaw (Stationary)

It’s the most commonly found saws in the market. The saw stands firmly on the floor with a tall structure. It’s attached pulleys assist the saw to move always and cut different materials. It equips with a fine-toothed blade that can rip through most wooden materials as well as can pierce through plastic and metals.

However, it may limit the depth of cutting, and you need to be patient to get accurate cuts.

2. Benchtop Band Saw

Benchtop band saws stand between a typical table saw and a jigsaw. Within their short space, they can produce excellent power. To get an intricate and quick cutting, most homeowner prefers to use the benchtop band saw. And thanks to their compact size, they can easily fit in almost anywhere.

3. Horizontal Band Saw

The horizontal band saw comes with a cutting blade that is positioned horizontally, and it is meant to cut down into the stock. Horizontal band saws are preferred by both professional woodworkers and amateur.

If you want something to cut large stock down to size, horizontal band saws will excel, but when you want to make intricate shapes or produce curved lines, they are not very useful.

4. Vertical Band Saw

These saws are called Vertical band saws because of their vertical cutting position. In most cases, they will be driven by an electric motor through the best transmission.

The blade on a vertical band saw will rotate on a fixed track that is between the drive wheel mounted beneath the worktable and the idler wheel that is mounted above the worktable.

5. Portable Band Saw

Portable band saws are the perfect choice if you need to use a band saw on the go. Portable band saws are the smallest and lightest among all band saw types.

They are easy to carry around. And despite their small size, these portable band saws are still quite versatile as they can be used to make straight edge cut, cut curved lines, and irregular shapes as well.

6. Table Saw

As the name suggests, table saws stand on a large table with rugged legs. The sturdy platform helps the saw to cut large woodblocks with ease.

Its blade is made for performing depth and accurate cuts. However, since it cuts blocks from its bottom, you need to push the blocks with safety. The best way is to use a push stick.

Types Of Table Saws

7. Cabinet Table saw

A cabinet table saw is an ideal piece of equipment for someone with serious woodworking requirements. These machines are built for stability, performance, and longevity.

Cabinet table saws are capable of cutting even the thickest of wood without breaking a sweat, making them suitable for professional woodworkers. These saws can be used continuously, all day long, and they are also great for people who don’t like handling vibrating saws.

8. Hybrid Table Saw

A Hybrid table saw is the combination of the best features of a cabinet saw, and the best attributes of a portable contractor saw.

It enables you to create cost-effective and efficient results with a durable workshop cabinet. A Hybrid table saw allows you to hold and cut your choice of materials. It enables you to complete projects professionally and efficiently, offering accuracy and precision with every movement.

9. Contractor Table Saw

A contractor table saw packs more power than its portable versions. They are not easy to carry or transport; however, they are strong enough to handle all types of projects and can accommodate boards of various sizes as well.

These saws feature a more powerful motor, greater torque, and larger tables than portable saws. They can handle woodworking and construction jobs without breaking the bank.

10. Jobsite Table Saw

Jobsite table saws are compact as well as portable and feature robust components and produce accurate results. They have direct drive motors, and their power and durability make them suitable for heavy-duty use.

Jobsite table saws also have the presence of a stand. Most of the jobsite table saw also comes with transport wheels and features such as dust collection ports, riving knives, and onboard storage space are generally considered standard for this type of table saw.

11. Portable Table Saw

Portable table saws tend to be less powerful and less costly than the cabinet type. For these reasons, they are a quite popular choice amongst hobbyists.

However, these portable table saws still pack enough power to handle heavy-duty jobs, and they are a great choice for job site or backyard workshop.

12. Chainsaw

A chainsaw is a specialized handheld power tool. It has a robust chain attached to its ripping teeth. It is a type of bandsaw that you can use for heavy-duty works.

Probably, the most common use of a chainsaw is to cut bushes and trees in woods or large property areas. It is useful in wooded areas.

Types Of Chainsaw

13. Manual Pocket Chainsaw

A manual pocket chainsaw is a portable saw that is primarily used as a part of survival gear. Basically, the pocket saw is a chainsaw chain with handles of ropes on both ends. You can wrap the chains around a wood piece and pull on each side with both your hands to cut.

A pocket chainsaw, as its name suggests, can be carried in your pocket. This gear can be very useful for people who like hiking.

14. Battery Powered Chainsaw

The name says it all. A battery-powered chainsaw is literally a chainsaw that is powered by a battery. The battery is integrated into the main housing of the chainsaw itself.

This type of saw gives you complete freedom of movement as there is no electric cord to tie you in a limit. These tools are also lightweight, therefore, comfortable to hold for prolong use and low maintenance.

15. Corded-Electric Chainsaws

A corded electric chainsaw has an electric power cord that needs to be connected to an extension cord and plugged into an external power source or electric outlet.

Unlike cordless chainsaws, corded ones never run out of juice, and they tend to be more powerful than the battery-powered versions. However, you always need to have a power source nearby to operate them, and your accessibility is limited by the cord. Generally, they are able to cut through tougher and thicker logs than cordless saws.

16. Gas-Powered Chainsaws

Chainsaws that are powered by gas tend to be the most powerful ones. With their fast chain speed, they can cut smoothly and quickly. And compared to electric models, the operator needs to put less pressure on a gas-powered one, making them the ideal choice for heavy-duty jobs.

However, they also tend to be heavier and noisier than their electric counterparts. They also require fueling and emit exhaust fumes. But for heavy-duty tasks, gas-powered chainsaws are your best bet.

17. Pole Chainsaws

Cutting limbs or branches that are a bit far above your head is not easy. And using a chainsaw while on a ladder is never recommended as it could result in a tragic accident.

That’s where a pole saw come in handy. A pole chainsaw is a saw connected to a pole. It’s a saw at the end of a long pole, which you can use to reach places that are normally out of reach. Genius, isn’t it?

18. Pneumatic Chainsaws

Pneumatic chainsaws are air-powered saws. To work with a pneumatic chainsaw, you will need to have a compressor.

They are useful in work situations where you are not allowed to use gas-powered chainsaws nor electric-powered chainsaws.

19. Circular Saw

Circular saw, aka, skill saw, is also a power saw. Its teeth diameter is about 7.25-9 inches that can cut through most wood, plastics, and metal with precision. It is one of the most commons saw that you would see these days.

It has two different types- sidewinder and worm drives. Furthermore, it has a height adjustment facility. You can, however, adjust the height with its lever. This is beneficial for depth cutting and accuracy.

You can even use it to cut aluminum.

Types Of Circular Saw

20. Sidewinder Circular Saws

Basically, a Sidewinder circular saw is a saw with a motor in line with the gearing, so the saw is more compact, and the blade spins faster.

This particular saw is a great choice for a hobbyist. They are easy to set up, use, and maintain. In comparison to other types of saws, lightweight and compactness are probably the two main advantages of these saws.

21. Worm Drive Circular Saws

Worm drive saws produce more accurate cuts and have a greater cutting capacity, but are also pricier and heavier. It is a type of circular saw that features a rear motor and its gears orient at 45-degree angles.

A worm drive saw is a stronger and longer saw than other models on the market. It makes cutting difficult and dense pieces of wood easier. They are suitable for cutting metals and other strong materials and ideal for professionals.

22. Hypoid Circular Saws

Hypoid saws come with more torque and power in comparison to some other types of saws.

Since gears drive the motor, it can deliver a significant amount of power, which allows you to cut through big pieces of lumber, plywood, and so on. Professionals are the ones that profit most with Hypoid saws as they know how to use the full potential of these models and turn them into a worthy investments.

23. Abrasive Circular Saws

Abrasive saws are usually used for cutting materials that are harder than woods. Since teeth bounce off most hard materials, abrasive saws do away with teeth entirely and come with a flat blade that resembles a pizza cutter.

These saws can be fixed to a table or radial arm, or handheld. They are effective at cutting pipe, tile, asphalt, and concrete. Their blades tend to be made of cubic boron nitride or diamond.

24. Track Saw

Track saws look similar to circular saws, but they are mounted on a track or a metal guide rail system. The cutting blade runs along the track.

With this versatile power tool, you can cut through sheets of materials such as doors, sheets of plywood, melamine, and MDF accurately and easily. These useful hand tools are made to handle tasks that a standard circular model simply can’t handle.

25. Metal Cutting Circular Saw

Metal Cutting Circular Saws are explicitly made for cutting metals. Metal is tougher to cut and more rigid than wood. And there is also the worry of sparks from metal-on-metal contact and the metal shards that get thrown from the blade.

Metal Cutting Circular Saws are designed in a way that offers protection from those sparks and shards. They tend to have a bit smaller blade than other standard circular saw and generally cut more slowly.

26. Concrete Circular Saws

Concrete saws are an alternative to toothless abrasive saws for cutting through high-resistance, hard materials such as metal and concrete. Instead of relinquishing teeth entirely, concrete saws use a special arrangement of teeth constructed out of an industrial diamond or something nearly as hard.

27. Tile saw

As the name suggests, a tile saw specializes in cutting tiles into different shapes and sizes. The tile saw lets you perform straight and clean cuts without much of difficulty.

The saw helps to get tiles without chips and damaged edges. Depending on the style, tile saws can be categorized into different types, such as benchtop and free-standing. The saw is used mostly by contractors and builders.

Types Of Tile Saws

28. Manual Tile Saw

Manual Tile Saws are designed to be accurate and fast, and they are also portable.

They are primarily designed to cut ceramic and porcelain tiles. Additional diamond-coated blades are also available to allow your cutter to handle glass.

29. Wet Tile Saw

A wet tile saw is a machine that uses a water-cooled diamond blade to cut tiles. The diamond blade has no teeth, making it ideal for more delicate cutting requirements.

Usually, a wet tile saw comes with a sliding table that feeds the tile into an overhead blade. They can cut very hard tiles and even glasses with the right blade.

30. Chop saw

Chop saw despite having a massive size; it is a portable one. That gives it an unthinkable edge over other saws. It is, in fact, the mobile version of a standard circular saw. Depending on the work type, it has two variants, masonry, and metal cutting releases.

It comes with a connected water line to reduce specks of dust at work. It also comes with an abrasive feature with the blade letting you cut anything.

31. Jigsaw

It is one of the most potent types of saws with a rugged reciprocating blade. The saw is used for performing plywood cuts customized cuts of metal sheets.

The jigsaw comes with sharp teeth to assist in precise cuts. You can also use it for creating curves in wood or metal.

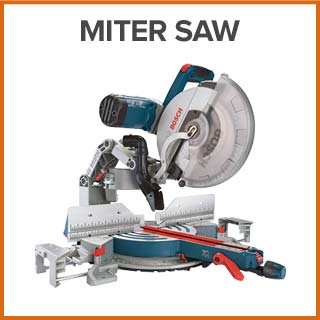

32. Miter Saw

The miter saw is an electric saw that you can use for precise measurements. The multipurpose saw can be sued for perpendicular cuts across the grain and for cutting across the thickness of ay board.

The blade of the saw comes in different sizes and shapes for achieving high accuracy at work. It will maximize your potential investment.

33. Oscillating Saw

Oscillating saws are useful for cutting in the limited space, thanks to its unique shape and vibrating blade. The saw is capable of handling sawing, sanding, grinding, and cutting different materials.

Orthopedic surgeons use the sterilized oscillating saw in operation theaters for years. Besides, carpenters, artisans, and flooring workers use the saw for clean and sharp cuts. It also comes with a variable speed controller.

34. Pole Saw

The name pole saw is itself self-explanatory. There’s a saw at the end of a regular pole.

The power source of a pole saw can be anything like gas, electric, or battery. However, pole saws are also available in manual form. With an attached pruning saw, the pole saw is ideal for trimming trees. So, it is a must-have saw for homeowners.

It is ideal for creating punctures and holes through panels. It is also useful for making the starter hole that you can use later for other power tools.

Types Of Pole Saws

35. Electric Pole Saw

An electric pole saw is powered by electricity and needs to be plugged into an electric outlet with an extension cord. While being limited by a cord might not seem fascinating, this design does offer some advantages.

They are cheap, powerful, and can run continuously. And there is no need for any refuel or change of batteries.

36. Gas Pole Saw

Gas pole saws, as their name suggests, get powered by gasoline. They are the most powerful and versatile tool you can own for pruning trees. They are an excellent option if you are working in a remote setting. Gas pole saws are great heavy-duty tasks.

37. Manual Pole Saw

A manual pole saw is a tree trimming tool that has a saw attached to the end of a long pole. This tool allows you to prune or trim tree limbs that are above your head and not easily reachable. Normally, a manual pole saw is ideal for small gardens with few trees.

38. Cordless Pole saw

A cordless pole saw gets powered by a battery. They can be used anywhere since you are not tied to an electric cord. They require rechargeable batteries to operate.

However, these tools are less powerful than their gas counterparts.

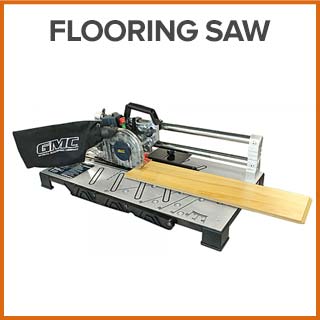

39. Flooring Saw

This is a portable power saw. You can use it for re-sawing floors to fit into perfectly. It is useful for working on the laminated, hardwood, and bamboo floor to give them an elegant finishing.

Unlike the table saw or miter saw used for floor finishing, the flooring saw is portable types of wood saws.

Due to its portability, the saw is an excellent way to save time. Since you don’t have to transport the material, you can fully concentrate on finishing with the flooring saw.

40. Panel Saw

Panel saw likewise its name cut thin woods into different sizes for creating dashboards with them. You can use the panel saw for making vertical and horizontal panels. It also supports large panel creation.

Among all types of saws, panel saw is the most cost-effective. The saw is ideal for the cabinet and sign-making industry.

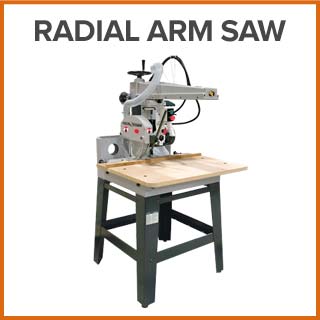

41. Radial Arm Saw

Radial arm saw equips with an extended motor and blade. Both the blade and motor are positioned on a table.

It is useful for miter cuts, compound cuts, bevels, and so on. Moreover, you can also interchange its blade with the circular saw. The radial arm saw is ideal for performing long cuts and crosscuts.

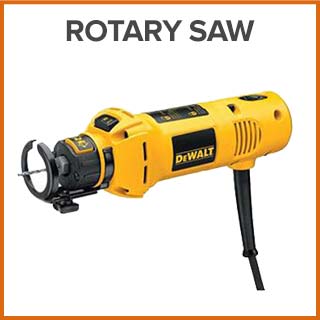

42. Rotary Saw

The rotatory saw comes with a small screwdriver type handle. Likewise, a keyhole saw, the rotary saw is most appropriate for paneling, drywall, and other small cuts. It is also ideal for repairing and accessing walls at ease.

The saw is identical to a drill appearance and best for cuts without a pilot hole.

43. Reciprocating Saw

The blade of the reciprocating saw is moveable quickly in back and forth, which is much like a jigsaw. People often call their edge as Sawzall.

Thanks to its parallel blade, you can cut underneath the wall and wood joints with better precision. If you want to demolish something, you must use the reciprocating saw.

Types Of Reciprocating Saw

44. Cordless Reciprocating saw

Battery-powered reciprocating saws are called cordless reciprocating saw. They can run as long as their battery supports them. They are, by far, the most convenient type.

45. Corded reciprocating saw

Corded reciprocating saws can be limited as they need an electric power source nearby. Usually, this isn’t an issue. You can continuously use a reciprocating saw without worrying about battery limitations. They tend to be the most powerful, as well.

46. Track Saw

Track saw gets an edge over any saws when it comes to effortless, precise cuts. In reality, track saw is a modified version of a regular circular saw to perform jobs that a circular saw can’t do.

It follows a specific guideline to achieve ultra-precise cuts. It quickly moves along the straight line that negates any chances of accidents.

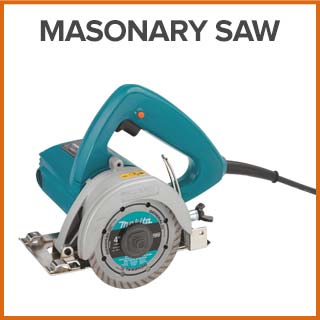

47. Masonry Saw

Masonry saw is mostly used for cutting large concrete blocks into useable shapes for construction work. It comes with a pistol or trigger like grip.

Its teeth and blades are more significant than most other types of electric saws. It also has a deep gullet that helps you to carry the specks of dust with ease.

Frequently Asked Questions (FAQs)

What is the best saw for woodworking?

Both handsaws and reciprocating saws are best for woodworking. However, you can use different types of wood saws to perform carpentry, depending on which kind of woodwork you will perform.

Do I need to sharpen the blade of saws?

Yes, it’s mandatory that you use a sharp blade. If the module becomes dull, you may need to put more effort. It also results in inferior cuts. So, you must sharpen the blade or buy a new one when it gets dull.

Conclusion

The market is booming with different types of saws. You must try to know about them to opt for the best one for your work.

The 35 variances of saws described here are all excellent at work, and you would love them at the workplace. That’s all for today.