If you’re the owner of a Stihl M Tronic chainsaw for an extended time, you know how well it performs in your backyard. That being said, you must also be aware of a few of its vexing issues. Sometimes the problem is clear and easy to fix, sometimes it’s more complicated.

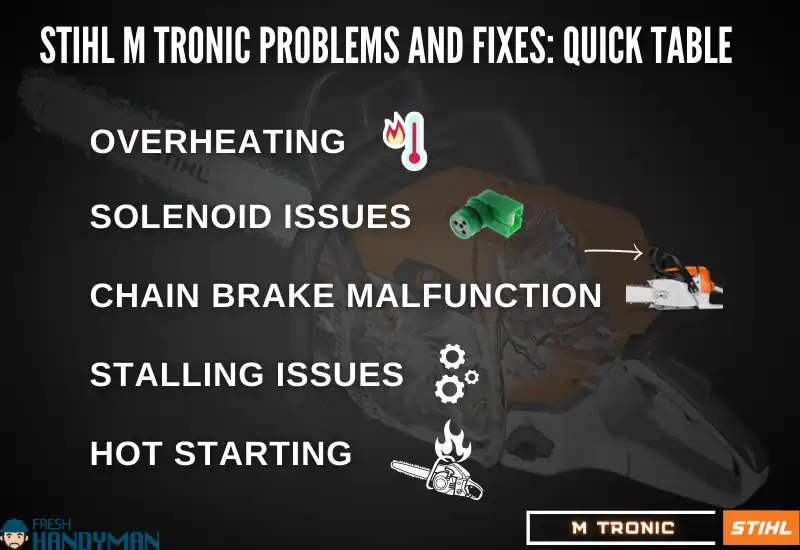

The most common problems that occur are overheating of the machine, issues with the solenoid, malfunction of the chain brake, stalling issues and sometimes hot starting.

Don’t panic. I’ll walk you through the most common problems that occur with the M-Tronic chainsaw and how to fix them. Furthermore, you’ll learn to reset your machine after completing the repairs from this write-up. So, finish it up.

Stihl M Tronic Problems and Fixes: Quick Table

The Stihl M Tronic has a lot going for it, but there are some common issues that you’ll want to keep an eye out for. Here’s a quick table of the most common problems and how to fix them.

| Stihl M Tronic Problems | Quick Solutions |

|---|---|

| Overheating | Clean up the air filter and ensure the exact oil-fuel ratio |

| Solenoid problem | Remove the debris and if necessary, replace it |

| Chain brake problem | Contact the servicing center |

| Hot start issue | Examine the exhaust system as well as the fuel tank |

| Stalling problem | Use exact fuel and if required, replace the solenoid valve |

Problems and Fixes of Stihl M Tronic: Comprehensive Discussion

I’ll go over the issue and how to solve it as thoroughly as possible down below.

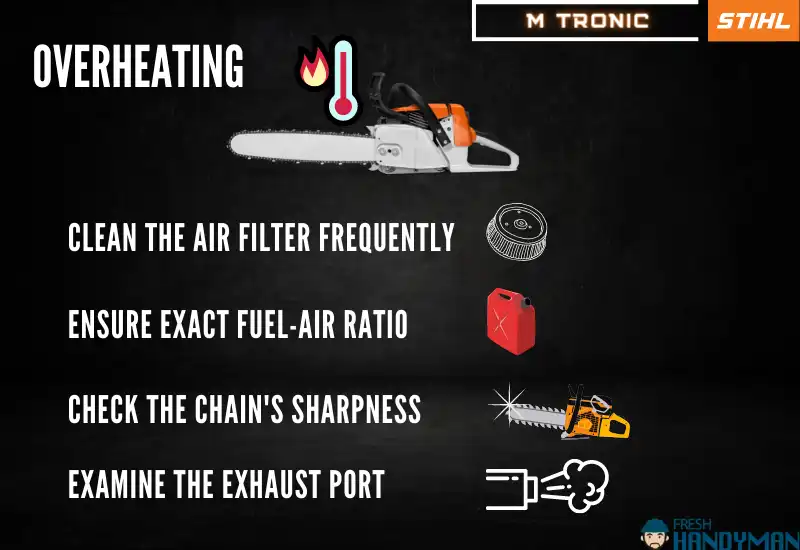

Problem 1: Overheating

The main cause of your M- Tronic overheating is a shortage of oil in the fuel-air mixture. Not only that, if the air filter and exhaust port stay blocked or clogged throughout, overheating will occur.

Aside from that, a sharp chain uses the typical amount of power while cutting, whereas a dull one consumes more power which also potentially causes overheating.

Process of Fixing

- Thoroughly clean up the air filter frequently.

- Ensure that the fuel-air ratio is exact.

- Double-check whether the chain is in sharp shape.

- Examine the exhaust port to ensure that it’s not blocked.

If you follow the steps each time before starting your saw, you’ll be most likely able to avoid this problem.

Read Also: 7 Most Common Stihl MS 271 Problems and Solutions

Problem 2: Solenoid Problem

The internal plastic of the fuel filter could be compromised if dirt larger than 30 microns enters it. Now, when dirt travels into the gasoline tank, the solenoid begins to wear down quickly.

If you encounter that your saw doesn’t restart or idle when it’s hot, it’s likely that the solenoid is worn out. This occurs whenever a solenoid valve leaks, allowing an enormous amount of gasoline to be entered into the engine.

Process of Fixing

- Always try to keep the fuel tank as tidy as possible

- Try to clean up the top of the kombi to prevent it from getting in the fuel tank

- By opening and shutting the fuel solenoid, which stands in for the carburetor’s manually adjustable screws, you can modify the quantity of fuel that the machine of your chainsaw receives.

- Make it a habit to thoroughly clean or spray the machine after each woodcutting session.

Read Also: 5 Common Stihl MS 661 Problems and Solutions to Fix Them

Problem 3: Chain Brake Problem

The chain brake can appear tight at times which eventually jams it. Now there can be two things that can cause this problem.

Well, it’s possible that the chain is stuck in place or that some debris is keeping the chainsaw’s hand guard from moving at all while the chain brake is engaged. However, both causes result in the chain brake not working properly.

An important thing to keep in mind is don’t ever use an M Tronic while operating a chain brake, as it can cause intense injury.

Process of Fixing

- When the chain brake starts to fail, cease using the saw right away.

- Verify that nothing is preventing the outward chain brake system from working.

- I strongly urge you to get in touch with the maintenance center if the problem seems severe

Read Also: Stihl MS 391 Problems, Troubleshooting With Solutions

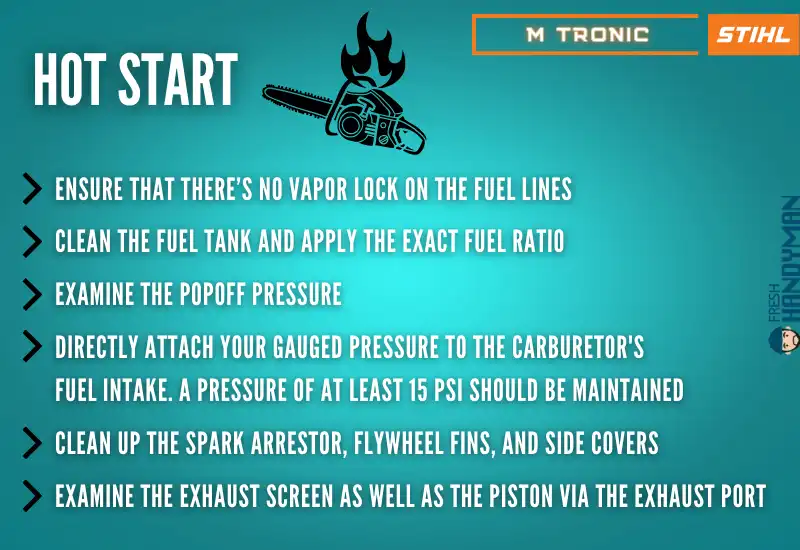

Problem 4: Hot Start

Though most models of Stihl M-Tronic fire up from a cold position and run half a tank smoothly, they all share a hot start issue. Usually, the solenoid’s setting is flooding or wide open. And a pretty fine system could malfunction if your saw gets too hot and has difficulties starting.

Fuel tanks can commonly develop vapor trapped owing to current gas components.

Besides, you could also face problems if you utilize winter fuel in a hot area.

Process of Fixing

- Check the fuel tank to ensure that there’s no vapor lock on the fuel lines when your chainsaw isn’t starting when hot.

- Clean the fuel tank and apply the exact fuel ratio. Along with that, inspect the carburetor to find any sort of gasoline obstructions.

- Examine the Popoff pressure, which permits gasoline to push its way out of the carb bore. Nonetheless, if there is insufficient Popoff pressure, you can flood the saw when it’s off. The MT will try to compensate for this when it is operating. But it can’t do it, whenever the saw is switched off.

- Now, directly attach your gauged pressure to the carburetor’s fuel intake. A pressure of at least 15 psi should be maintained. They are usually set to 25 or higher.

- Clean up the spark arrestor, flywheel fins, and side covers.

- Examine the exhaust screen as well as the piston via the exhaust port. Check to see if the layout is okay.

Problem 5: Stalling

When you start to notice that your M-Tronic chainsaw creates weird noise but stops when you hit the throttle, it’s a sure fuel problem. Rarely, an improperly sealed solenoid valve also causes stalling.

Process of Fixing

- After extended usage, clean the saw, especially the carburetor.

- If you discover that the solenoid seal is faulty, replace it.

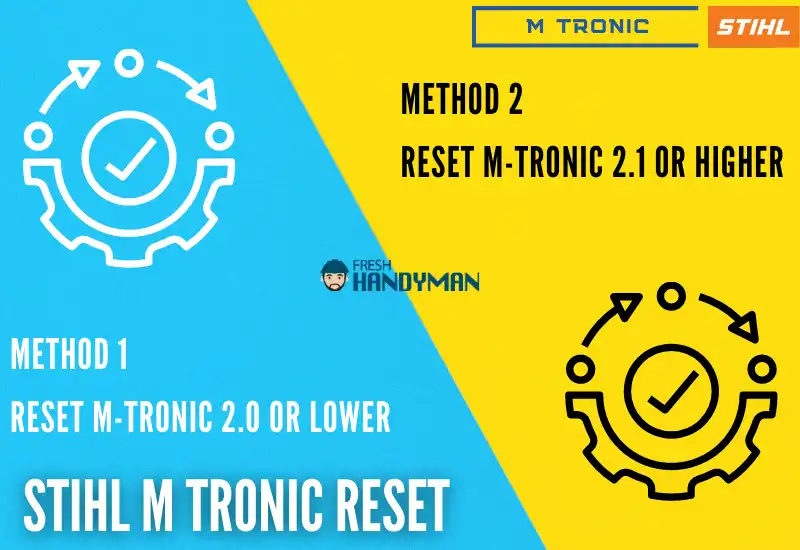

Stihl M Tronic Reset

If you’re having trouble with your machine, it may be time to reset the M-Tronic. You can reset the machine following two methods.

>>Follow method 1 to reset M-Tronic 2.0 or lower machines.

>>Follow method 2 to reset M-Tronic 2.1 or higher machines.

Method 1

- Take off the scabbard

- Make sure to on the chain brake

- Set the machine to Cold start mode

- Turn on the machine in that mode and keep it running for 90 seconds at least

- Don’t accelerate or hit the throttle of the saw at this time

- Turn off the machine after 90 seconds

- Re-calibration is completed and the machine is ready to work

Method 2

- Detach the scabbard.

- Make sure to on the chain brake.

- Set the machine to Cold start mode.

- Turn on the machine in that mode and keep it running for 30 seconds but not above 60 seconds.

- Don’t accelerate or hit the throttle of the saw at this time.

- Turn off the chain brake.

- For a minimum of 30 seconds, completely squeeze the throttle.

- During calibrating, the engine speed changes substantially.

- Now, when the engine speed reduces significantly, return the throttle to the idle state.

- After that, when the engine gets back to idle speed, turn on the chain brake and shut the engine off.

- Finally, the calibration of your saw is complete, and it is now ready for use.

Stihl M Tronic Diagnostic Tool

When you think of Stihl M-Tronic diagnostics, you’ll need the best tool. With that being said, the MDG-1 tool is the perfect solution for your Stihl machinery.

It comes with everything you need to perform checks on your equipment, allowing you to identify problems before they become big issues.

This diagnostic tool will help you determine whether there are any problems with your carburetor or fuel lines. It can also tell you if there are any issues with the spark plug or ignition coil.

Plus, If there are any problems with these parts of your machine then this diagnostic tool will tell you exactly what it is. As a result, you’ll be able to do repairs quickly and easily before they cause major damage to other parts of your machine.

FAQ

How to know whether my Stihl saw is M Tronic or not?

To determine whether yours is an M Tronic or not, check the CE label. Yours is an M Tronic if the label has a higher or 2.1 highlight. If there is no CE marking present, your device is probably an older model.

What does M-Tronic Mean?

The Stihl has an engine management technology called M-Tronic that constantly controls and monitors the air and fuel mix. You don’t have to manually modify the fuel quality, octane levels, temperature fluctuations, or air filters. For optimal performance, the system will automatically sort out everything.

Which saw Can I use Instead of M Tronic?

If you’re looking for an alternative chainsaw that can handle all your tree-trimming needs, look no further than the Husqvarna 540i XP. With its 40cc power and weight, this tool is perfect for pros who want a gas-free chainsaw to cut down trees with ease.

Conclusion

When something goes wrong with your Stihl M-Tronic, it can be one of the most frustrating and difficult experiences. This is especially true when you have spent well over a hundred dollars on the saw in the first place. However, since I went into great detail about the Stihl M Tronic problems and solutions.

In the end, it’s still a fantastic chainsaw that’s well worth your money. You won’t experience these issues quite frequently if you continue with routine maintenance and inspection.