While the Stihl MS 170 is an affordable and high-quality chainsaw, it has several problems that make it challenging to use.

Perhaps the biggest issue is that the machine won’t even start. In addition, there are other problems associated with the clutch, carburetor, and air filter.

Fortunately, I discovered some effective ways to solve these issues. I will elaborate on each of those solutions in the article. So let’s get started without further ado!

Quick Solutions to Stihl 170’s Problems

In case you are in a hurry and would like to resolve issues on your chainsaw fast, check out this quick-fix table.

| Stihl MS 170 Troubleshooting | Quick Fix |

|---|---|

| Why won’t my Stihl MS170 start? | Replace the spark plug or get rid of the vapor |

| Fuel problems, such as not getting fuel | Inspect the impulse line on the boot and assemble it properly |

| Issues with the clutch | Install a new clutch |

| Air filter overheating | Unclog the carb thorough cleaning |

| Oiler on Stihl 462 is not working | The oiler requires adjustment |

STIHL MS 170 Gas Chainsaw

- Bar Length: 16 in

- Engine Type: 2 Cycle

- Engine Displacement: 30.1 cubic centimetre

- Maximum Cutting Diameter: 17 inch

- Antivibration Handle: Yes

- CARB Compliant: Yes

Detailed Solutions to Stihl MS170 Common Problems

Sometimes, quick solutions are not enough to solve problems. The following detailed guide will be most helpful in such a situation.

Common Problem #1: Stihl MS170 Starting Problems

Whenever I come across users of the Stihl 170, they complain that the saw will not power up. Several factors could be responsible for this, including the spark plug, the vapor lock, or the carburetor.

The Solution

The majority of the 170s problems are related to starting. I have come up with three different solutions that can help fix the issue.

Let’s see them. If one method doesn’t work, try another.

1. Eliminating Vapor

It is highly likely that the cause of the 170 not starting is vapor lock. There is usually a buildup of vapor in the tank.

This is exactly why tank vents play a crucial role. However, they will be useless if dirt and debris are blocking them.

Make sure you clean all of them. As soon as you let the vents open, the vapor will release, and the saw should begin to work.

2. Spark Plug Replacement

The chainsaw can also fail to start when the spark plug wears out. In that case, replacement would be the only viable option.

3. Cleaning the Carburetor

Chainsaw carburetors tend to be dirty quite often. The dirt may prevent the MS170 from starting.

You may want to get the carburetor cleaned or serviced by a mechanic. In such circumstances, a carburetor repair kit can be invaluable.

If the starting issues still persist, it could be because you are starting the saw incorrectly.

At the end of the article, I have outlined a comprehensive guide to starting the Stihl 170 chainsaw. Hopefully, that will assist you in starting the power tool smoothly.

Also Read: Stihl MS170 VS MS171 (Detailed Comparison)

Common Problem #2: Stihl MS170 Fuel Problems

Another issue reported by MS170 users is that the chainsaw does not receive fuel. It could occur for multiple reasons, but the boot’s line is most likely to blame.

The Solution

There is a high probability that the impulse line of the boot has been placed incorrectly. Hence check the boot thoroughly, especially the impulse line.

If you discover a bad line placement, you must correct it by reassembling it. This should allow the boot to function again and fix the fuel problems.

Related: Stihl 462 Problems and Solutions

Common Problem #3: Stihl MS170 Clutch Problems

Most clutch failures occur when the clutch wears out. A new clutch should solve the problem.

The Solution

Here is how you can get rid of the old clutch and replace it with a fresh one.

- Before beginning the procedure, ensure the chain is free.

- There should be two nuts holding the sprocket cover in place. Use a spanner to loosen them.

- Now pick a screwdriver to loosen the tensioning screws. You will locate them close to the guide bar.

- You are now all set to unbolt the sprocket cover nuts. Consequently, the casing will come off, allowing you to remove the chain and bar.

- A circuit resides inside the chain sprocket. Use pliers to pull it out.

- The next step involves removing the chain sprocket, sprocket washer, and bearings. Keep them in a place where you can recall them.

- Grab a flathead screwdriver and unscrew the shroud.

- As soon as you’ve detached the shroud, you can take off the air filter as well.

- Pick up the spanner again. The intent is to loosen the spark plug. After that, you can simply remove it by hand.

- Next, slide the piston stop into the spark plug entry. What this does is lock the crank. The clutch should thus be easy to unscrew.

- Inspect the clutch for signs of wear or damage. If you notice anything serious, consider replacing it.

- Once you install the replacement clutch, reassemble everything the same way you disassembled it.

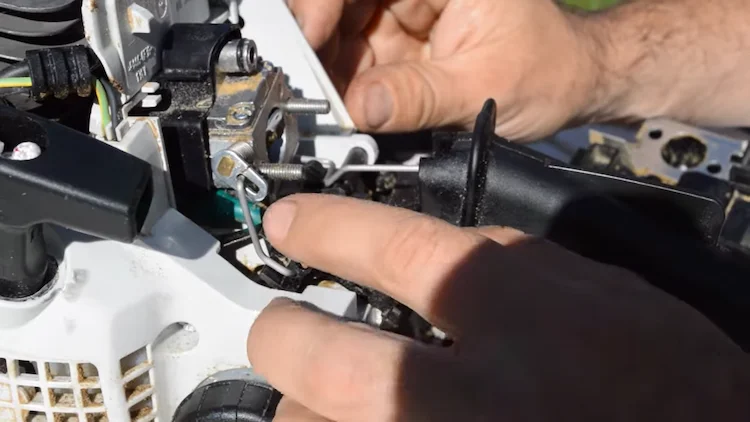

Common Problem #4: Stihl MS 170 Carb Problems

The carb on the Stihl MS 170 chainsaw has been known to have various issues. When the carb malfunctions, it is challenging to use the tool. This is due to the carburetor’s big responsibility for air/fuel mixture supply.

The Solution

Carb issues are more common in 170 saws because they use fixed jet carburetors. They tend to clog up and corrode more rapidly than other carburetors.

You can obviously try unscrewing the jet and thoroughly cleaning it. However, I must inform you that your efforts may be in vain since the problem is unlikely to go away so easily.

Replacing the carb seems the best course of action.

Related: Stihl MS 391 Problems, Troubleshooting With Solutions

Common Problem #5: Stihl MS170 Chain Lubrication Problems

There have been numerous reports about chain lubrication problems with MS 170 chainsaws recently. I have identified two possible remedies for these issues, which I will discuss below.

The Solution

Problems with chain lubrication will arise primarily when sawdust blocks the oil delivery mechanism. Remove the bar and chain, then clean as much dirt and debris as you can.

It is possible to find dirt in the oil inlet hole too. Such confined parts are, however, quite difficult to clean. In that case, you need to utilize compressed air for dust and dirt removal.

Common Problem #6: Stihl MS170 Air Filter Problems

Another frustrating issue with Stihl 170 saws is the poor air filter. It may overheat the chainsaw from time to time. A good solution is to clean the filter.

The Solution

Other chainsaws do not include air filter covers. Therefore, cleaning those filters involves a number of complicated steps.

Fortunately, the MS170 does have the cover. Thus, accessing the filter is as simple as opening the cover. Afterward, you can easily clean it.

How to Start a New Stihl MS170?

Failure to start is not always the fault of the chainsaw. Maybe you are the one who is not starting the MS170 systematically.

Hence, I have provided detailed instructions below to help you start the saw properly.

STEP – 1: Supplying Gas and Oil

To begin with, fill up the chainsaw with sufficient gas and oil. After that, remove the tool’s cover.

STEP – 2: Activating the Chain Brake

In the second step, you have to turn on the chain brake. Never skip this step since it is a crucial safety measure.

STEP – 3: Adjusting the Choke

Now would be the right time to alter the choke setting. Multiple chokes are available. You should select the full choke.

However, before you turn the choke to full, engage the throttle first. Without pressing the throttle, you won’t be able to opt for a full choke. Release the throttle afterward.

STEP – 4: Pulling the Rope

Once the full choke has been set, pull the rope firmly to start the machine. As this is your first time starting the saw, it may take up to six pulls. That’s perfectly normal.

While pulling, you must place one hand on the top of the handle and one foot on the bottom of the chainsaw.

STEP – 5: Disabling the Chain Brake

After starting the tool, you should press the throttle once more. It will set the choke to idle and disengage the chain brake. The chain is now ready to spin at a decent speed.

If the chainsaw shuts off during idle, you may need to pull it again to restart it. A single pull would suffice.

To Sum Up

Since people use chainsaws primarily outdoors, the internal parts are always likely to get dirty. As mentioned in the article, sometimes all it takes is a simple cleaning to resolve most chainsaw problems.

If cleaning does not help, perhaps it is time to replace the malfunctioning component.

Here is another article I wrote offering solutions to the problems with the STIHL 462.